Aluminum Castings for the Manufacturing, Foundry & Tooling Industries

Plaster mold and rubber plaster mold (RPM) services for castings that require thin wall construction, near die cast finishes and high metallurgical integrity.

Plaster mold and rubber plaster mold (RPM) services for castings that require thin wall construction, near die cast finishes and high metallurgical integrity.

These processes are a quick and relatively inexpensive way to produce aluminum and zinc castings. With typical cast roughness of Ra 16 and wall thickness of 0.080″ to 0.120″, we are capable of casting as thin as 0.030″ wall thickness.

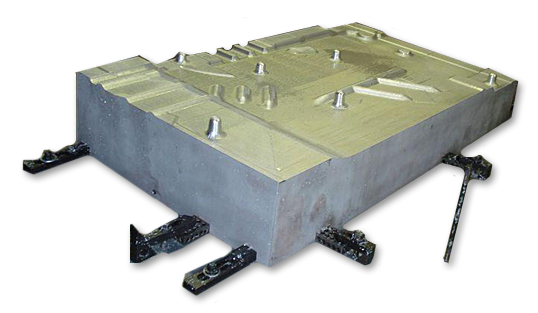

Specialized Castings can create your match plate, cope & drag or core box tooling from a master or from supplied 3D data; if 3D data is supplied, we can also have the tooling cut from aluminum or steel billet.

Specialized Castings can create your match plate, cope & drag or core box tooling from a master or from supplied 3D data; if 3D data is supplied, we can also have the tooling cut from aluminum or steel billet.

Most tooling can be configured with 1 pattern or with multiples depending on the pattern and the tooling size.

Specialized Castings is a leading provider of quality custom prototype & short-run castings. Prototype castings can be produced fast to meet project deadlines sometimes in as few as 7 days with typical lead times of 1 to 2 weeks. We use a combination of the following different prototype methods that best suit your project:

Specialized Castings is a leading provider of quality custom prototype & short-run castings. Prototype castings can be produced fast to meet project deadlines sometimes in as few as 7 days with typical lead times of 1 to 2 weeks. We use a combination of the following different prototype methods that best suit your project:

– Rubber Plaster Molds (RPM)

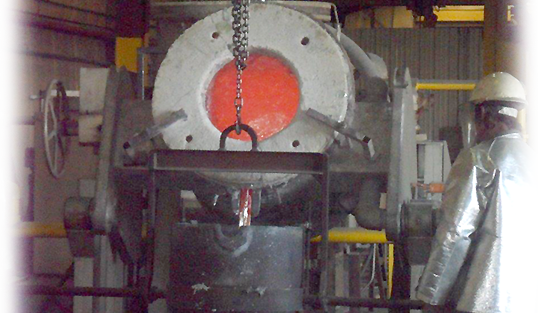

– Greensand method

– No-bake or Air-Set

– SLA (Stereo Lithography)