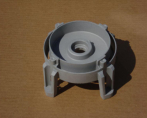

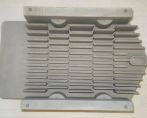

Specialized Castings offers plaster molding and rubber plaster molding (RPM) services for castings that require thin wall construction, near die cast finishes and high metallurgical integrity. With typical cast roughness of Ra 16 and wall thickness of 0.080″ to 0.120″, we are capable of casting as thin as 0.030″ wall thickness.

Versatile Plaster Molding

The plaster molds are typically used for prototypes and low-quantity production runs, but they are also an alternative to die cast parts and pre-production parts during the fabrication of die-cast molds. While our plaster molds have typical draft angles of 1 to 2 degrees, in some applications we can produce plaster molds with zero degree draft angles, corner radii and fillets.

The RPM castings have the near die-cast finishes and have the ability to simulate the mechanical & thermal properties associated with die-cast parts. RPM castings range from ounces to 25 lbs and mold sizes up to 36″ x 36″.

Plaster Molding Capabilities

| Maximum Mold Weight | Up to 2000 lbs |

| Flask Size | 12″ x 12″ 36″ x 48″ |

| Design Tolerances | +/- 0.020 |

| Draft Angles | 2+ Degrees |

| Pouring Capabilities | Ounces to 300 lbs |

| Equipment | (7) Furnaces (4) Molding Stations (4) Continuous High Speed Mixers (4) Grinding Stations Sandblasting Stations |

| Secondary Services | Pattern Making CNC Machining Certified Inspection Heat Treating and Coatings X-ray Misc. Testing |